Core Competency

32.768 kHz Tuning Fork Crystal

32.768 kHz Tuning Fork Crystal

Vertical Integration, In-House Design and Production

Siward's innovation and breakthrough in photolithography wafer micro-electromechanical technology, combined with the ability to grow synthetic quartz crystal, integrating upstream and downstream resources, make our 32.768 kHz tuning fork crystal self-sufficient from design, development to production, and further enhances the competitive advantage in the industry. Major production sizes, from most common 3.2 x 1.5 mm, miniature 2.0 x 1.2 mm, and to ultra-miniature 1.6 x 1.0 mm.

Process Flow Chart

The production process of 32.768 kHz tuning fork crystal is divided into three steps, synthetic quartz crystal bar growing in Tainan facility, photolithography technology in Hsinchu wafer design center, and dedicated production line in Tainan factory. The production capacity is self-sufficient and does not need to seek external support. This vertical integration not only to ensure the supply of high-quality crystals, but also to fully control of production capacity and delivery time.

All Size Available and Design Ability

Multiple package size available, from most common size 3.2 x 1.5 mm to ultra-miniature size 2.0 x 1.2 mm and 1.6 x 1.0 mm. Siward has blank design capabilities with photolithography technology to meet different applications and customer needs.

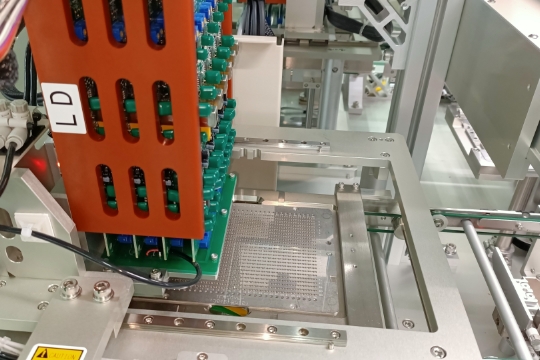

Dedicated Production Line

Siward's 32.768 kHz tuning fork crystal production lines are highly automated and dedicated lines, which set up to ensure product quality and meet the highest requirements.

32.768 kHz Tuning Fork Crystal Wafer

Technical Aspects

For the photolithography technology of high-precision products, the most important thing is the requirement of product size fineness. Based on photolithography technology, the processing accuracy are capable within 2 microns, which is more stable and higher production capacity than traditional methods.

Innovation

Since great dimensional accuracy are required for tuning fork products, it is crucial to control critical dimensions during manufacturing. At present, there are not many competitors, due to high difficulty in miniaturization. Siward adopts the latest photolithography technology, which provides more stable production conditions for miniaturized products, not only shortens the production cycle, but also greatly improves the electrical performance, which is a remarkable breakthrough in production yield and reliability.

Feasibility & Commerciality

There are many types of tuning fork-type quartz oscillators on the market, and the most demanded is 3.2 x 1.5 mm package. When confronting the rising demands for 2.0 x 1.2 mm and 1.6 x 1.0 mm, it is first to lower the cost when the production capacity is increased. Siward possess leading photolithography technology which allows to meet the demands of different product types rapidly. Together with the improvement of the yield rate, we can make the maximum capacity with the lowest cost, not only can occupy a place in the market, but also gains a competitive edge.